With the development of the automobile industry, the global car ownership is increasing year by year, and all kinds of electric vehicles are also emerging. The resulting energy crisis, air pollution and climate warming are becoming more and more serious, and the policies and regulations of governments on automobile emission are becoming more and more stringent. Whether for fuel vehicles or electric vehicles, vehicle lightweight is an important means to effectively improve the competitiveness of products. One of the main ways is to use light metal parts to replace traditional steel parts, so as to reduce the emission of fuel vehicles and improve the endurance of electric vehicle batteries. The density of aluminum alloy is small, and its density is only one third of that of steel. At the same time, its thermal conductivity, processability and corrosion resistance are better than that of steel. The primary weight reduction effect of typical aluminum alloy parts can reach 30% ~ 40%, and the secondary weight reduction effect can be further increased to 50%. The main production processes of aluminum alloy parts are divided into casting and forging. The parts produced by casting process are mainly shell and support, such as engine cylinder head, gearbox shell, steering gear shell, engine bracket, steering gear support, etc; The parts produced by forging process are mainly parts with high mechanical performance requirements, such as wheels, chassis suspension system control arm, steering knuckle, air conditioning compressor scroll, etc. Typical automotive aluminum forging materials aluminum alloy forging raw materials used in the automotive industry generally use extruded or cast bars, and its material brand generally comes from the registration of American Aluminum Association (AA), international organization for Standardization (ISO) and deformed aluminum alloy standards formulated by various countries. The standard for the designation of wrought aluminum alloy in China is GB / T 16474-2011 wrought aluminum and aluminum alloy designation. In addition, relevant national standards include GB / T 3190-2020 wrought aluminum and aluminum alloy chemical composition and GB / T 33910-2017 extruded aluminum and aluminum alloy profiles for automobile. The material grades of typical automotive aluminum forged parts are mainly 6 series, such as 6060, 6061, 6066 and 6082. Some products also need 2 series, 4 series, 5 series and 7 series materials, such as 2014, 4032, 5754 and 7075.

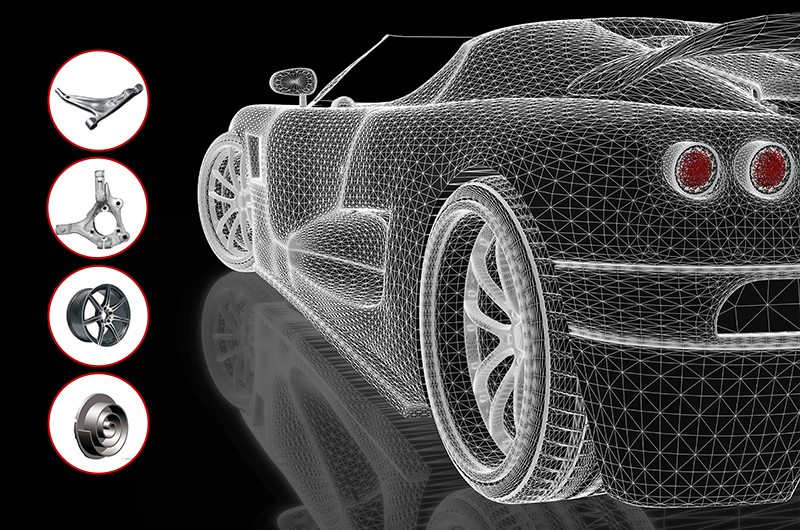

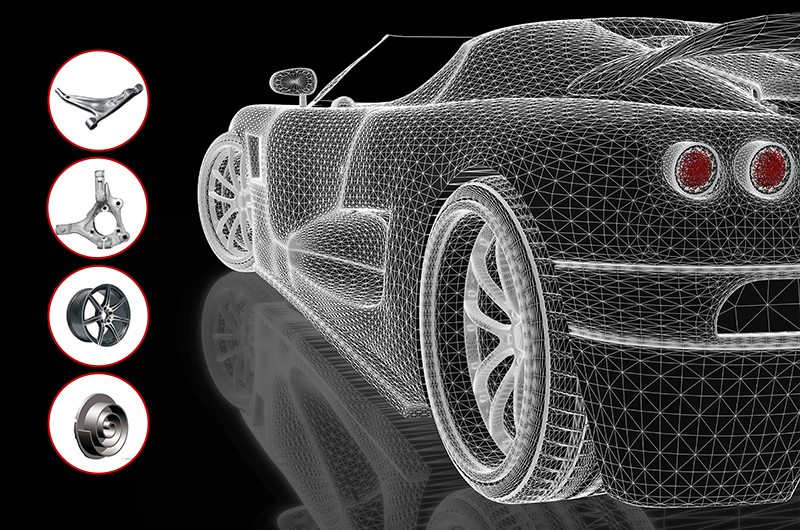

Typical aluminum forged parts and forming technology for automobile

Integral wheel

Aluminum alloy integrally forged wheel is a kind of product developed continuously based on the requirements of automobile lightweight, high efficiency and energy saving. It is generally made of 6061 and 6082 aluminum alloy. Compared with the traditional cast wheel, it has superior microstructure and performance, light weight, high strength and good surface quality. However, due to complex process and large equipment investment, its manufacturing cost remains high, It can only be used in high-end passenger cars and commercial vehicles. The forming process of integrally forged wheels generally selects different process flows according to different product structure characteristics, application scenarios and batches. The commonly used forming processes and their applications in the market are shown in Table 1. The integrally forged wheel usually needs post forging treatment such as heat treatment, machining and surface treatment after forging. T6 heat treatment process (solid solution treatment + artificial aging) is generally adopted for heat treatment to improve the strength of each part of the wheel.

Control arm

The automobile control arm, also known as the swing arm, is an important part of the automobile chassis system. Its comprehensive mechanical properties play a vital role in the safety and stability of the vehicle. It is generally made of 6082 aluminum alloy. The control arm is divided into front control arm and lower control arm. The front control arm is the guide and support of the suspension. Its deformation will affect the wheel positioning and reduce the driving stability; The lower control arm is mainly used to support the vehicle body, shock absorber and buffer the vibration during driving. The early control arms were mostly made of cast iron, cast steel or steel plate by stamping and welding. With the improvement of material processing technology, the forged aluminum alloy control arm is gradually replacing the steel control arm and realizing batch application on medium and high-end vehicles at home and abroad, such as Japanese Xuanyi, Xiaoke, Qijun, Korean Langdong, American iveo, carnival, European Suteng, Passat, etc. The typical forging process of aluminum alloy control arm generally includes blanking, heating, blank making, forming, trimming, heat treatment and surface cleaning. According to the different shape and structure of products, the billet making process can adopt roll forging, cross rolling and other methods, and some products also need to adopt bending and pre forging to reduce the difficulty of final forging. The heat treatment generally carries out solid solution and aging treatment to improve the mechanical properties of products. Shot blasting or sand blasting can be used for surface cleaning to remove the oxide skin on the workpiece surface and improve the mechanical properties of the workpiece.

Steering knuckle

The steering knuckle is the key structural part in the automobile front axle assembly and front suspension system. It connects the front axle and the steering system. It not only carries the whole weight of the automobile and transmits the steering power, but also bears the load generated by the impact from the ground and wheel lateral braking. It is a powerful guarantee for the safety of the automobile during driving. The steering knuckle is a complex security part in the automobile chassis components. The forging process of aluminum alloy steering knuckle generally includes blanking, heating, blank making, pre forging, final forging, trimming, heat treatment and surface cleaning. According to the product structure and forming difficulty, one heating or multiple heating can be carried out. The heating process can be before any process of blank making, pre forging and final forging. The heat treatment generally also adopts solid solution and aging treatment.

Scroll disk

The development process of automobile air conditioning compressor has experienced four generations. The first generation of compressors are reciprocating vertical piston compressors, and then evolved into the second generation of swash plate, rocker plate and radial radiation compressors, and then developed into the third generation of rotary compressors, such as rotary vane, rolling piston, screw and triangular rotor. Now the fourth generation of high-efficiency scroll compressors has been developed for more than 20 years, And realized industrialization and large-scale production. Scroll disk (Figure 5) is the key component of scroll compressor, which can be divided into moving disk and stationary disk. The material is generally 4032 aluminum silicon alloy, with complex structure and high performance requirements. At present, one-step or two-step back pressure forming and forging process is generally used at home and abroad, and some enterprises also use liquid die forging process