Aluminum alloy materials for automobile bodies mainly include 2000 series, 5000 series, 6000 series alloy plates, profiles, pipes and high-performance cast aluminum. Different types of aluminum alloy materials are used for different stressed parts.

Frame part: The most stressed part of the car body is made of 2000 series or 7000 series materials, which can be strengthened by heat treatment.

Skin part: The secondary stress-bearing part of the car body, using 5000 series or 6000 series materials.

Door part: use 5000 series or 6000 series materials.

Bottom plate part: use 5000 series or 6000 series material.

Interior part: use 1000 series or 5000 series materials, without heat treatment strengthening.

Seat part: 2000 series or 6000 series materials are used, which can be strengthened by heat treatment.

Casting: High-performance cast aluminum alloy is used, which can be strengthened by heat treatment.

Aluminum alloy plates mainly include 2000 series, 5000 series and 6000 series alloys.

2000 series alloy is an aluminum alloy that can be strengthened by heat treatment. It has excellent forgeability, high strength, good welding performance, and good baking strengthening effect, but its corrosion resistance is worse than other series of aluminum alloys. . At present, 2036 and 2022 alloys have been partially used in automobile body panels.

The 5000 series alloy is an aluminum alloy that cannot be strengthened by heat treatment. It has good corrosion resistance and welding performance. However, it may produce Lüdes line and delayed yield during processing deformation in the annealed state, so it is mainly used for shapes such as body inner panels. Complicated parts.

6000 series alloys belong to heat treatment strengthened aluminum alloys, which have higher strength, better plasticity and excellent corrosion resistance. Compared with steel plates, the yield strength and tensile strength of 6000 series 2T4 tempered plates are similar, and the hardening coefficient even exceeds that of steel plates. At present, 6009, 6010 and 6016 aluminum alloys are used in the outer and inner panels of automobile bodies because of their good plasticity and can achieve artificial aging during the spraying and baking process after forming to obtain higher strength. The Audi A8's body panels use this series of aluminum alloy. In addition, in order to enhance the cushioning capacity and fatigue strength of automobiles, VAW of Germany, KOK of Japan, and Southwest Aluminum of China have all developed and developed high-performance automotive aluminum plates and aluminum profiles based on this series of alloys. Currently, 6000 series alloys are the main force of body panels.

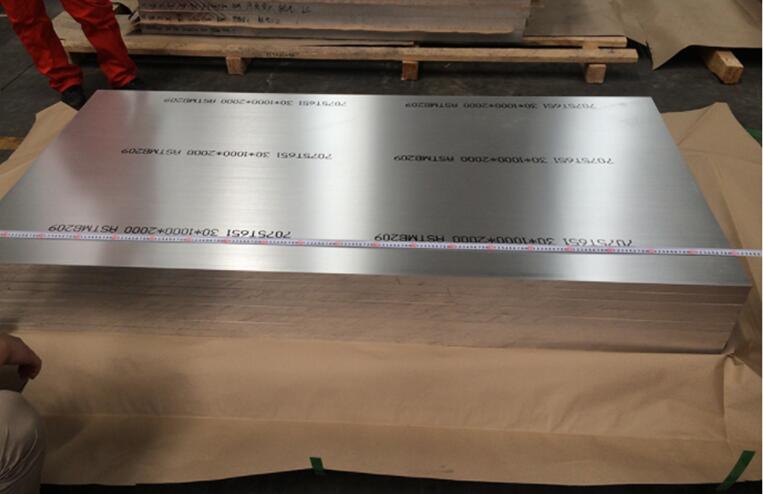

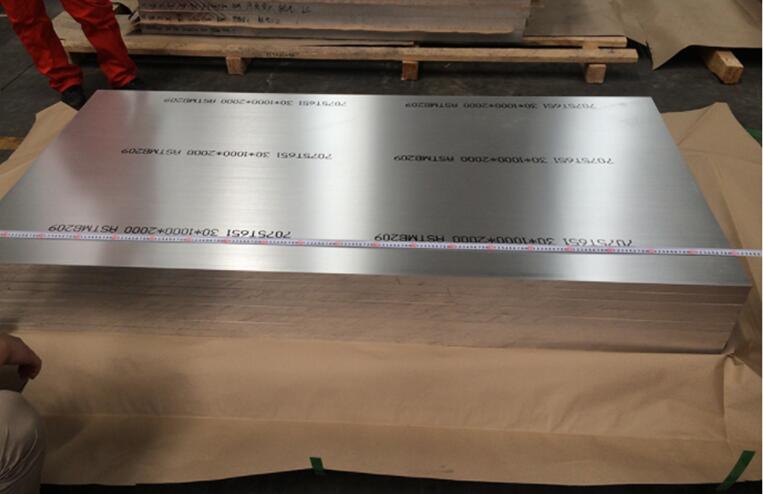

Henan Chalco is a well-known

automotive aluminum sheet supplier. Our

automotive sheet is currently in the leading position in China. Tesla's body aluminum is almost produced by Henan Chalco. In terms of extrusion profiles, Henan Chalco's products are equally competitive. .