The automobile industry is one of the largest and most important industries in the world. In a sense, the development level and strength of the automobile industry reflect the comprehensive national strength and competitiveness of a country.When it comes to cars, car lightening isn't just about reducing the weight of the car,

But on the premise of ensuring the strength and safety performance of the car, the application of reasonable design structure and the use of new materials instead of lightweight, automotive lightweight is the main means of energy saving and emission reduction.

Aluminum has the characteristics of low density, good corrosion resistance, and excellent plasticity, casting, forging, stamping process are applicable.In addition, aluminum is easy to recycle. Almost 90 percent of aluminum used in automobiles can be recovered and recycled.From the production cost, parts quality, material utilization and other aspects of comparison, aluminum alloy has become an indispensable important material in automobile production.

Automotive aluminum extrusions

Automotive aluminum extrusions because of its light weight, good rigidity, good processing performance, welding performance and other structural materials are widely used in various parts of the automobile.One of the

Automotive aluminum extrusions used in cars are electric car motor shell, car pedal, luggage rack, various automotive radiators, decorative parts, aluminum anti-collision beam and bumper, frame, body plate and so on.

There is demand for aluminum for car bodies. The use of aluminum for car body is a concern in the industry. According to the data, the 210 kg aluminum body is about 40% lighter than the corresponding steel body. Without changing the volume of the car, it can increase the speed and increase the riding space, so that the car can run smoothly and safely. Comfortable. At present, the main difficulty of aluminum body manufacturing is the stamping and welding performance. The aluminum body of the car developed by many foreign automobile companies mostly adopts the space frame structure, which is composed of aluminum extrusion, aluminum plate and aluminum casting. The main advantage is light weight. , Good rigidity, strong bearing capacity, small number of parts, short production cycle and low cost. Such as German Audi A8, A2, BMW Z9; Japanese Honda NBX car; American AMGeneral Hummer; Italian Aris off-road vehicle; British Storm infantry fighting vehicle, Land Rover off-road vehicle, etc.

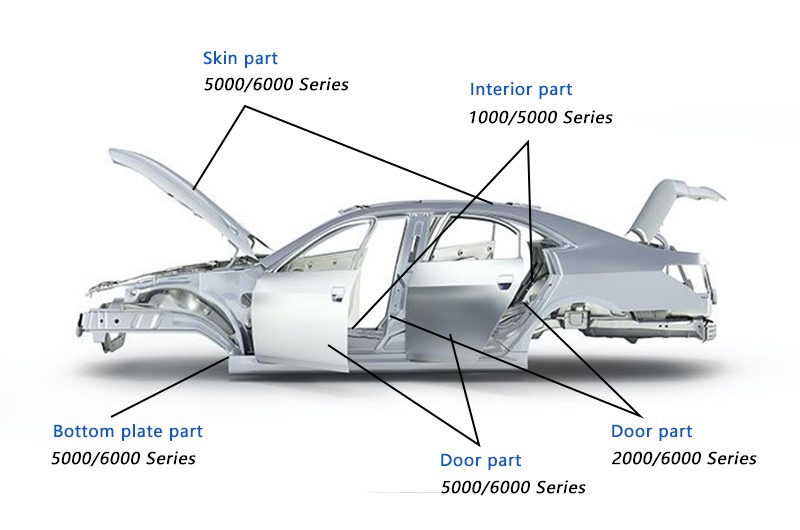

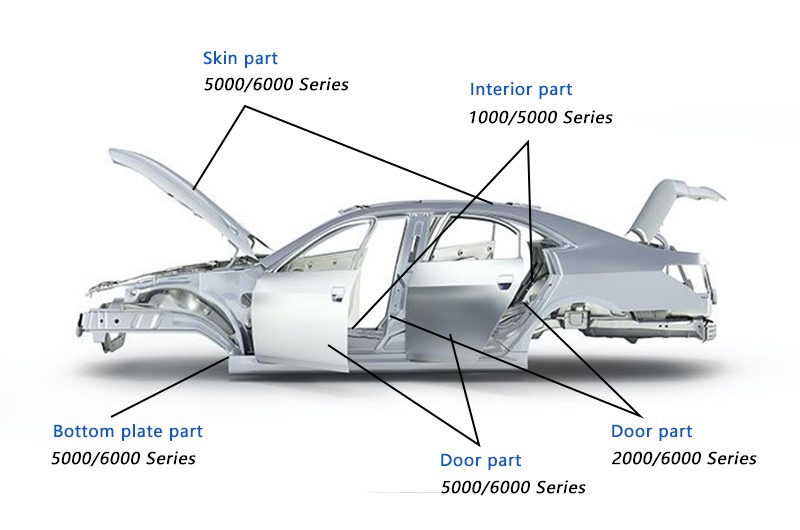

At present, the body of foreign cars is mainly made of deformed aluminum materials such as plates and extruded materials. In the United States, Japan and Europe, the main aluminum alloys for car bodies are 2000 series, 5000 series, 6000 series and 7000 series. The body stamping parts are larger in size and more complex in shape, and have higher requirements on the performance and production process performance of aluminum materials. Car outer body panels focus on strength, stiffness and surface quality. The world's car shells mainly use 6000 series alloys. Europe also uses 6000 series alloys with good formability, high strength and excellent corrosion resistance, such as 6016 Taijin, North America uses 6111 alloy, Japan chooses 5022 and 5023 alloys. The inner body panel pays attention to the forming process, and does not require high strength and surface quality, so 5000 series alloys are mostly used. The main grades of aluminum body, the United States uses 2036, 5182, 6009, 6010; France uses aluminum magnesium 5, CP483; Japan uses GC45, GCI50, GZ45, GV10, X660; Germany uses aluminum magnesium 3, etc. Bumpers, door and window frames, ceiling rails, etc., are made of oxidized extruded aluminum, and anodized to improve corrosion resistance and wear resistance. The main alloys are europium 6463, 6008, 6014, 9029, etc. 6111 alloy is generally selected for the protective plate and various cover plates. Practice has proved that 6009 and 6010 alloys are very promising materials. They can be artificially aged in the process of painting, drying and heating after forming, so that the strength reaches or exceeds that of low-carbon steel. Therefore, the deformed aluminum with paint baking strengthening effect will be reused in the automotive industry. The aluminum used in the car body has attracted the attention of my country's automobile industry. There are currently no suitable products for the selection of various deformed aluminum materials used in foreign car bodies. Joint development of non-ferrous processing industry.