Aluminum has been widely used in the world automobile industry and has become an important material for automobile manufacturing because of its excellent performance, good production technology and high material regeneration. Nowadays, countries all over the world pay great attention to the three major issues of energy, environment and safety, and urge the automobile industry to develop safe, reliable, high-speed, comfortable, energy-saving and environmental friendly modern vehicles. The main problem to be solved is vehicle lightweight. Weight reduction and energy saving has become one of the goals of modern automobile technology progress. The application of aluminum in automobile is an important way to realize automobile lightweight. Promoting the lightweight process is helpful to improve the service performance of automobile and bring great economic and social benefits.

Aluminum replaces the traditional steel to make cars, which can reduce the weight of the whole car by 30% ~ 40%. The research shows that every 1kg of aluminum used in the car can reduce the dead weight by 2.25kg, and the weight reduction effect is as high as 125%. At the same time, it can reduce the exhaust emission by 20kg in the whole service life of the car. That is, the weight reduction and emission effect ratio of aluminum is 1:2.25:20. Aluminum is easy to recycle. It is a material that can be recycled to the greatest extent other than steel. Almost 90% of automotive aluminum can be recycled and recycled. Today, with the rising awareness of environmental protection in the world, highly recyclable materials and products are increasingly reused. Therefore, aluminum makes a great contribution to promoting vehicle lightweight, reducing energy consumption and improving human living environment.

Aluminum has excellent physical and chemical properties. High conductivity, high thermal conductivity, corrosion resistance and small proportion are the reasons why it has been reused. Aluminum has good processing and mechanical properties. Its most remarkable feature is its versatility. The casting, forging and punching processes in industrial production are applicable. It is one of the few metals that can use a variety of casting processes to produce parts. It is the most suitable pressure casting process widely used in automobile production. At the same time, deformed aluminum can provide a variety of products for the automotive industry, such as plates, strips, foils, tubes, rods, wires, extruded materials and forgings with various section shapes. Aluminum has a long history in the automotive industry and has accumulated rich production experience, creating conditions for expanding the use of aluminum. Therefore, in terms of meeting the multi-purpose performance of automobile parts, aluminum is the most economical, practical and competitive material among engineering materials in terms of production cost, part quality, material utilization and adaptability of various processes.

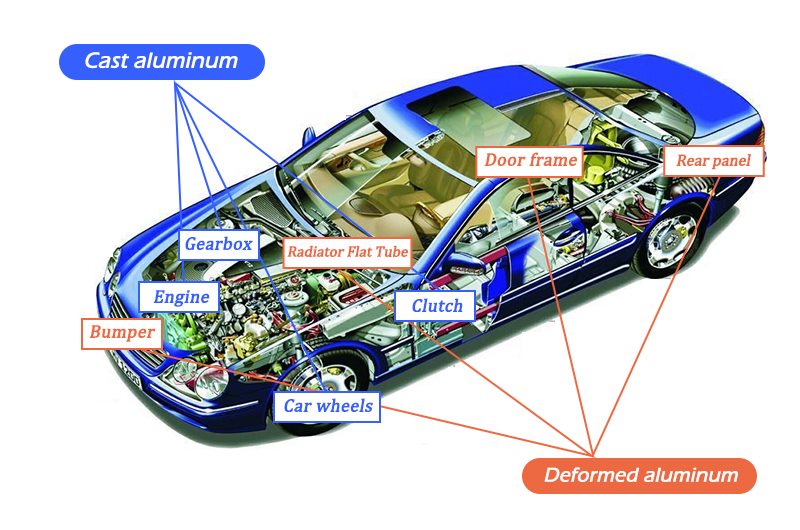

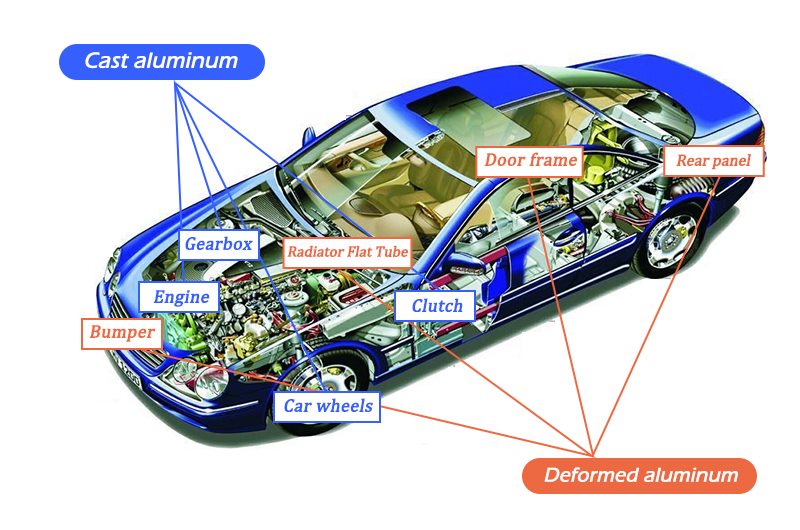

Automotive aluminum can be divided into cast aluminum and deformed aluminum (including forged aluminum). In order to obtain large production batch, high production efficiency and low part manufacturing cost, the automobile industry selects casting process to produce more aluminum parts, accounting for about 3 / 4 of aluminum materials. Aluminum castings are mainly used for engine system, transmission system, chassis walking system and other parts. Aluminum castings are mainly used in the gravity casting process of the whole vehicle, and aluminum castings and gear boxes are mainly used in the production of aluminum castings. The aluminum casting process accounts for about 65% of the aluminum castings used in the whole vehicle, and the aluminum casting process of the low-pressure casting system is used in the production of the engine. In recent years, great progress has been made in the application of aluminum castings for cars in China. The amount of aluminum used in engine, gearbox, clutch, aluminum wheel and other systems has increased rapidly. At present, aluminum castings are almost used in engine cylinder head, intake manifold, gearbox housing and clutch housing of domestic cars [...]

Deformed aluminum is mainly used in various heat exchanger systems of automobiles, car body systems, box cars, luxury bus component systems, etc. The deformed aluminum materials mainly used include plate, strip, foil, extruded round pipe and porous flat pipe, welded round pipe and flat pipe, extruded materials and forgings of various shapes, etc. At present, China's deformed aluminum materials are mainly used in various heat exchanger systems of cars, the trunk of box cars and luxury buses, while there are few deformed aluminum materials used in the body system of cars. Because the body system accounts for 20% ~ 30% of the total weight of cars, aluminum materials can generally reduce the weight by 40% ~ 50% instead of traditional materials. The aluminum used in the body of cars is the most concerned problem of the automobile industry, and will be the focus of expanding the use of deformed aluminum materials for domestic cars in the future.