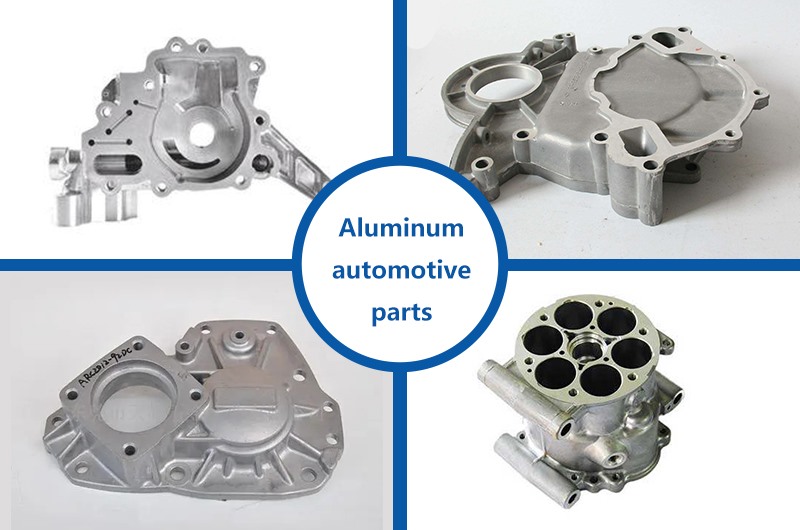

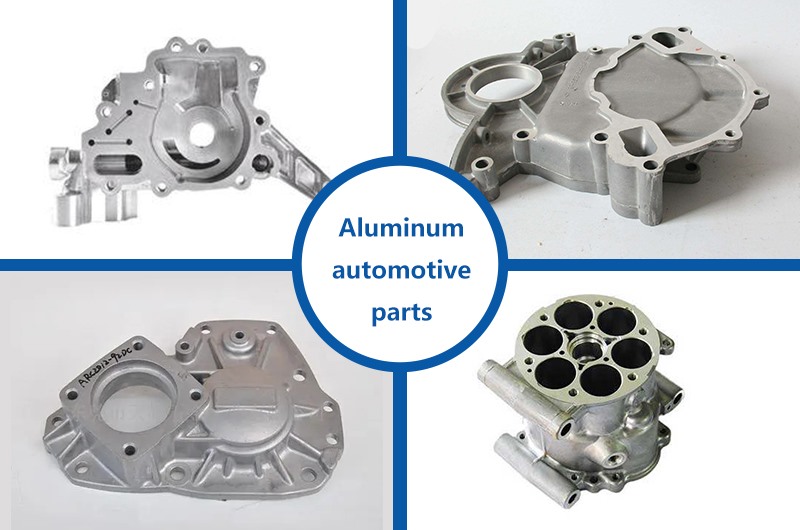

With the vigorous development of automobile industry, due to the needs of environmental protection and energy saving, automobile lightweight has become the trend of automobile development in the world. In the process of implementing automobile lightweight,

Aluminum automotive parts will give full play to its natural advantages and will be mainly used to transform and replace body materials. Automobile lightweight can be roughly divided into three categories: body lightweight, engine lightweight and chassis lightweight. Their purpose is to reduce the vehicle weight by using lighter materials on the premise of ensuring performance, so as to realize the function of energy conservation and environmental protection.

Obviously,

Aluminum automotive parts has its natural advantages in vehicle lightweight:

1、 The effect of weight reduction and energy saving is obvious. Aluminum has good mechanical properties. Its density is only 1 / 3 of that of steel. It has good thermal conductivity, second only to copper. Its machinability is 4.5 times higher than that of iron, and the oxide film naturally formed on its surface has good corrosion resistance. Therefore, aluminum has become the most ideal preferred material to realize automobile lightweight.

2、 The comfort and safety of passengers are improved. Aluminum alloy vehicle reduces the weight of the vehicle without reducing the vehicle capacity, reduces the center of gravity of the vehicle body, and makes the vehicle driving more stable and comfortable. Due to its good energy absorption,

Aluminum automotive parts has obvious advantages in collision safety. The deformation area in the front of the car will wrinkle during collision, which can absorb a lot of impact force, so as to protect the driver and passengers behind.

3、 Aluminum is easy to recycle. Aluminum products have little or only slight corrosion in the process of use. Among the conventional materials used in industry, the recovery value rate of aluminum is the highest. In the recycling process of aluminum materials - aluminum products - use - recycling recycled aluminum ingots - reprocessing into aluminum materials, the loss of aluminum is only about 5%, and its regeneration performance is higher than that of any common metal.