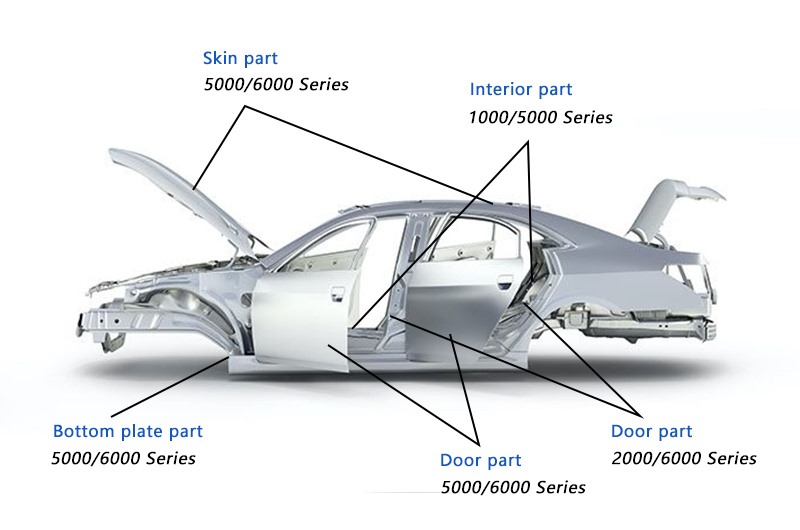

Aluminum alloy in automobile industry can be rolled with 2XXX series, 5xxx series, 6xxx series and 7xxx series aluminum alloy. Except for the 5xxx series aluminum alloy, the other three series are heat-treated and can strengthen the aluminum alloy. Their strength is further improved when coating and baking. The 661 aluminum plate, 6009 aluminum plate, 6010 aluminum plate, 7075 aluminum plate, 5083 aluminum plate, 5052 aluminum plate, 2024 aluminum plate, 2A12 aluminum plate, etc. are all suitable for rolling After the heat treatment, high strength and high rigidity aluminum plate for automobile can be obtained.

Good formability. The forming process of body and cover sheet metal parts is through stamping.

Aluminum alloy in automobile industry should have good stamping formability, that is, it has low yield ratio and high forming limit, and has quite high forming space under various stamping deformation stress states.

The surface is smooth.

Aluminum alloy in automobile industry must have good flanging ductility and consistent surface color performance after forming, that is, the formed sheet metal surface does not have a rolling Li · e, that is, a sliding line, which is caused by uneven grain or inclusion distribution, resulting in uneven surface deformation of the sheet metal, so that the surface has inconsistent luster after painting.

Good weldability. The good weldability can meet the requirements of welding automobile components after forming. The sheet metal shall have aging resistance stability to ensure that aging does not occur from the time when

Aluminum alloy in automobile industry leaves the factory to the time before stamping production, so as to prevent the rise of yield point of materials during stamping processing, and induce uneven surface deformation and wrinkling caused by Lucie 'and Zo · e, thus affecting the surface quality of automobile outer sheet.

Excellent bake hardenability. Automobile lightweight also requires high bake hardenability of sheet metal, that is, the yield strength of sheet metal increases obviously after stamping deformation and paint baking, so as to ensure high concave resistance of sheet metal parts after stamping and painting. The paint baking process of aluminum alloy sheet metal is compatible with the current paint baking process of sheet metal stamping parts.